Background

Reciprocating pumps (including diaphragm pumps, plunger pumps, and other

positive displacement pumps) are used in many applications, including

petroleum production facilities and refineries. Interactions with

connected pipelines and system parts must be taken into consideration as well

as system optimization with correct sizing of pulsation dampeners.

A Pulsation Analysis and mechanical review of piping

system is often necessary for new or existing reciprocating pumps systems to

avoid typical problems such as:

- excessive

pressure pulsations and piping vibration;

- pressure pulsation-induced cavitation;

- undesired

opening of PSVs due to pulsations;

- fatigue

failures to pipelines and components;

Scope

An acoustic analysis is recommended to optimize

overall system design by investigating the interaction between the pump and

pipeline with the following advantages:

– Reliable long-term operation: complying with defined

limit values for pressure pulsation and extending the service life of the

overall system;

– Increasing availability: Improving operating

reliability and lowering maintenance costs

Pulsation dampeners design options:

Our experience as a dampener manufacturer and acoustic

analysis engineering provide the best recommended options over our wide range

of products for a safe pumping system operation. Focusing on existing or new

pulsation dampeners installation performances.

If a preliminary piping layout is available as well as

pump and liquid information, a preliminary computation of static suction head

and pressure pulsations in the system, allow to select the correct pulsation

dampener (size and type). Similarly at discharge static pressure is generally

high and pulsations shall be lowered by suitable pulsation control to get

acceptable piping vibrations and avoid pressure safety valve chattering.

Calculation methods:

Two level of efforts are available according to API

674 STANDARD: Approach 1 and Approach 2.

Both methods use a state-of-the-art numerical

calculation method performed in Fox engineering department.

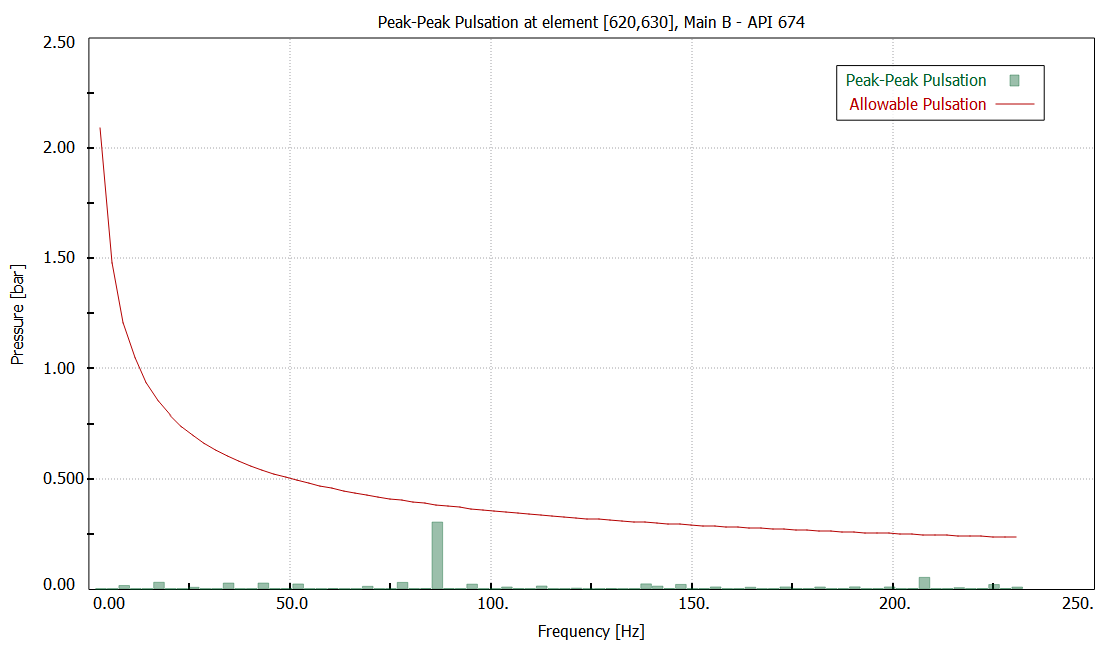

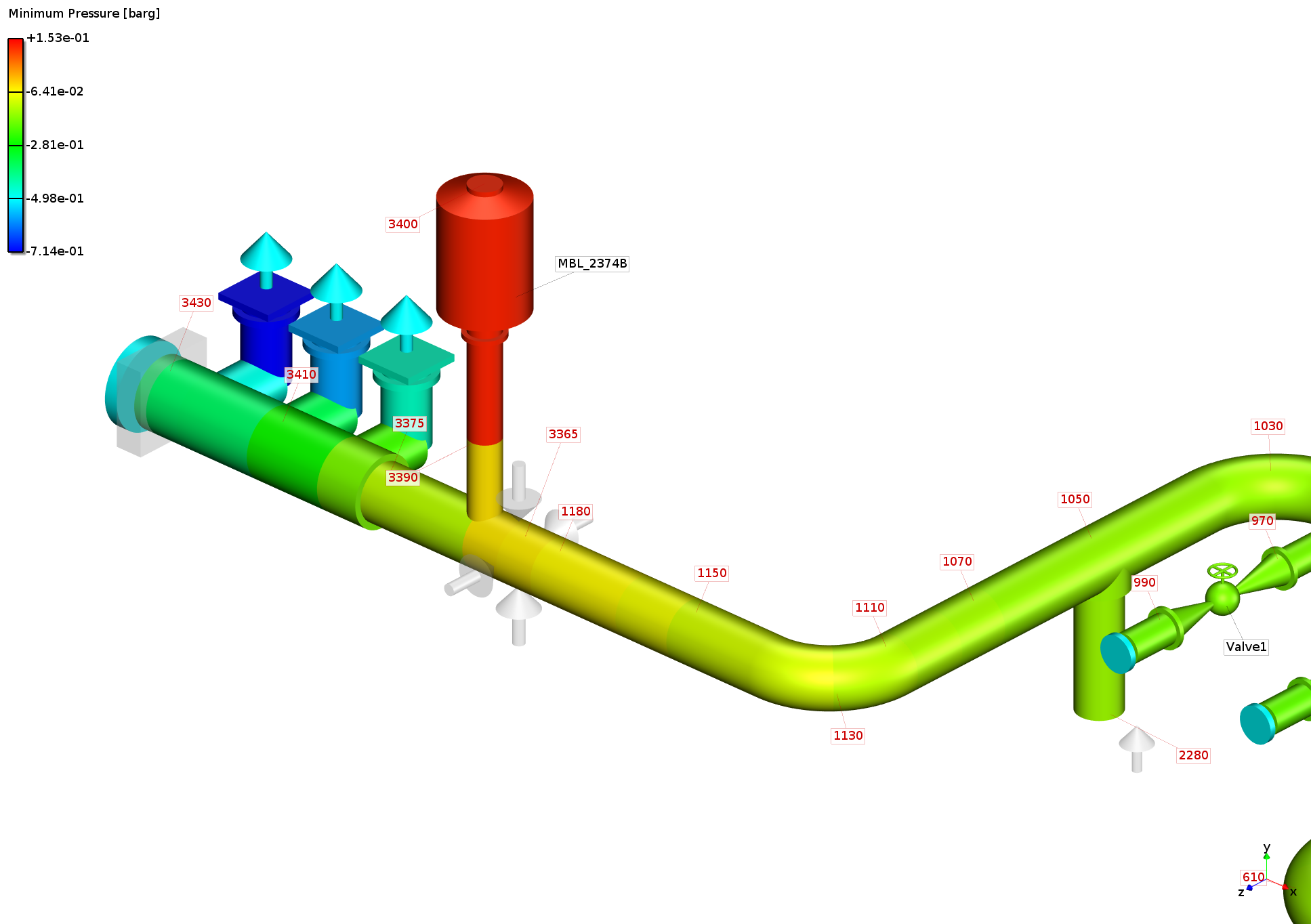

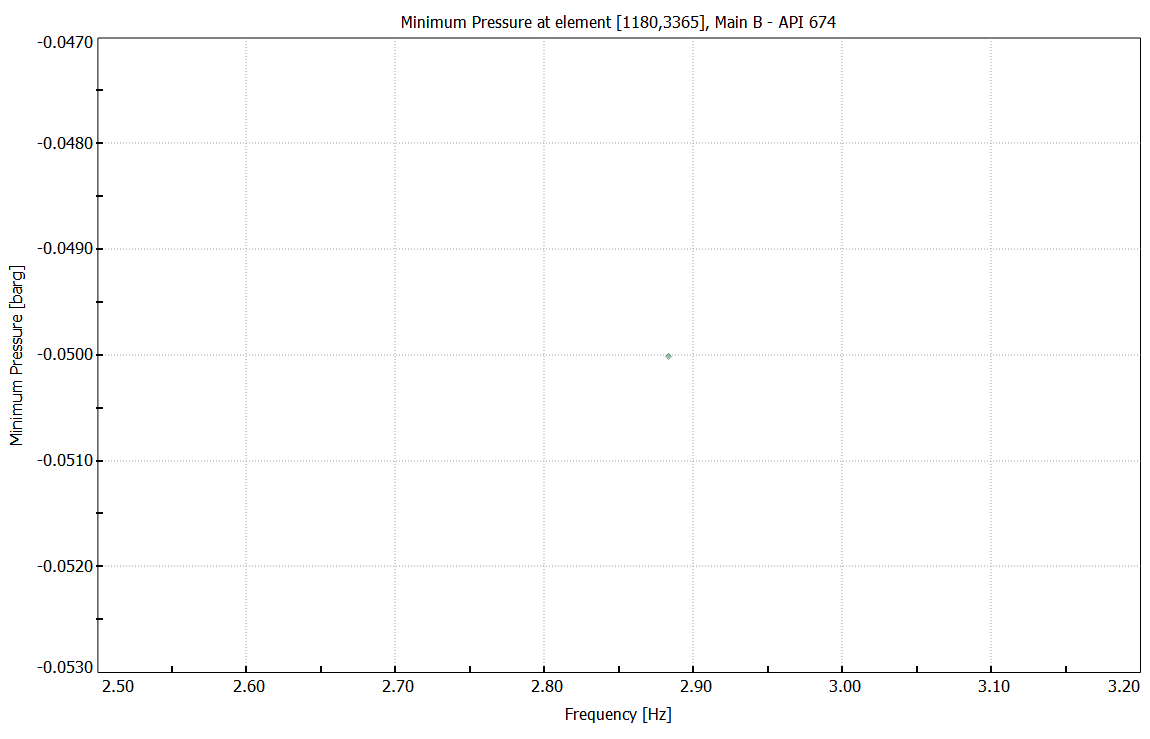

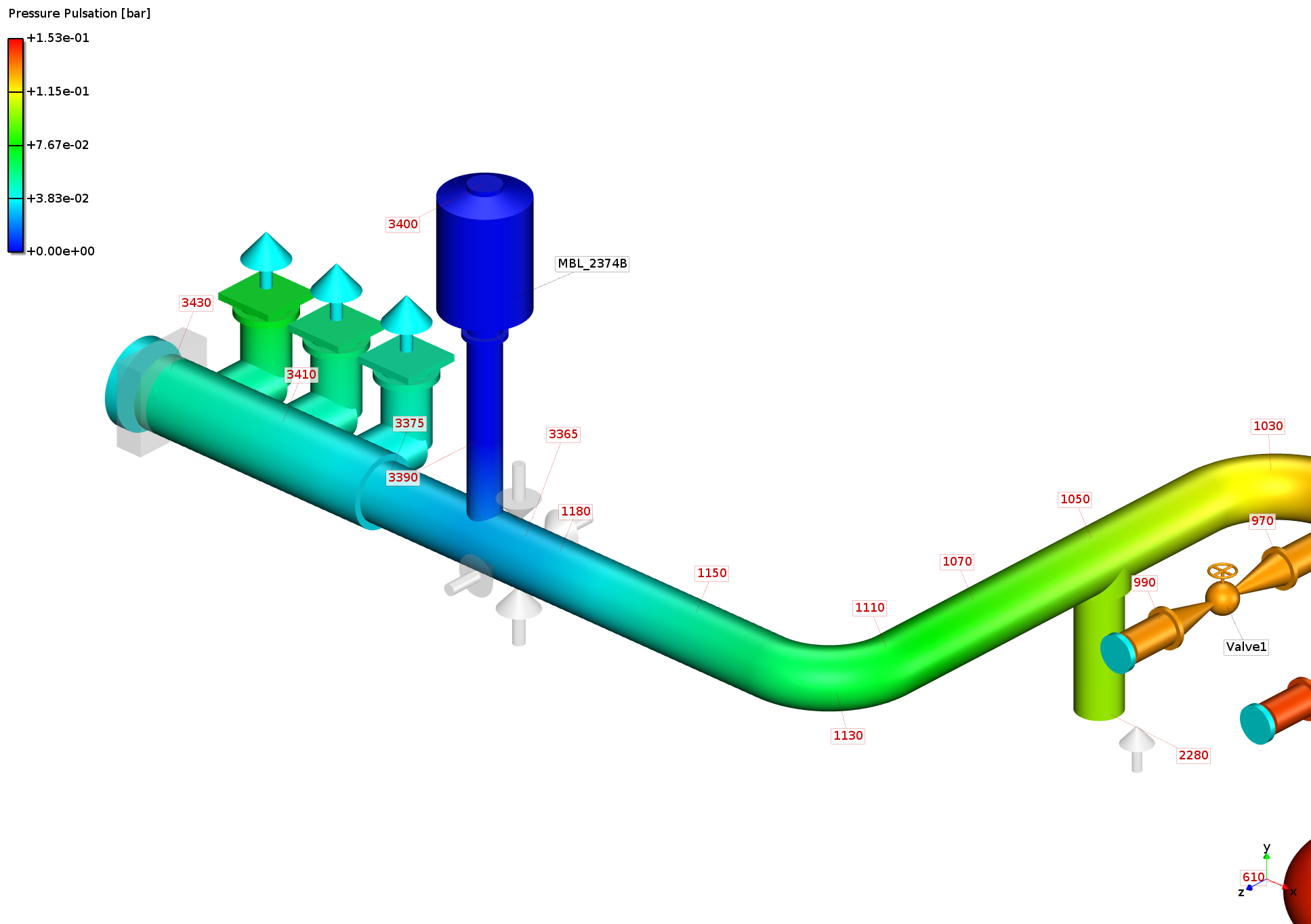

Design Approach 2

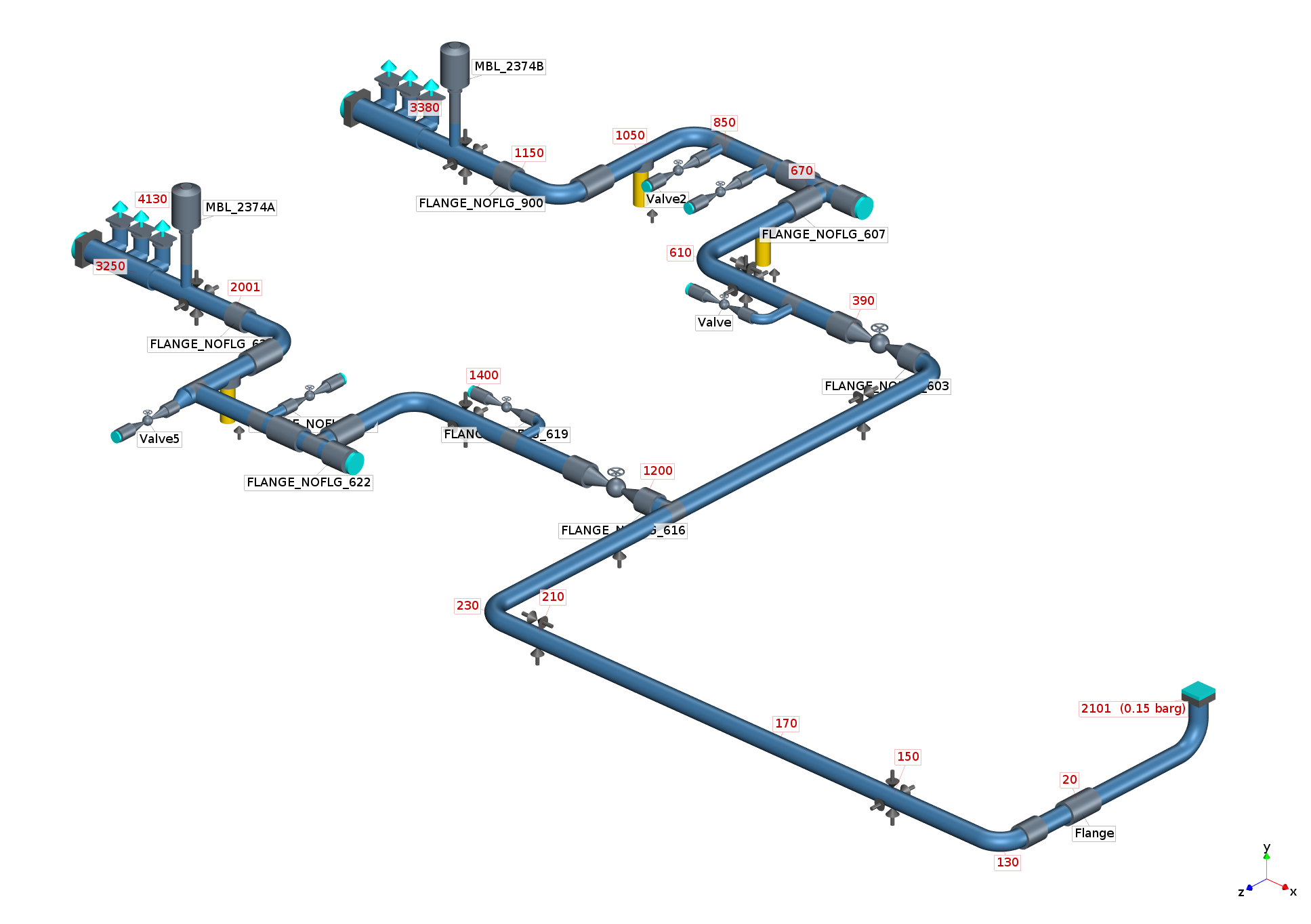

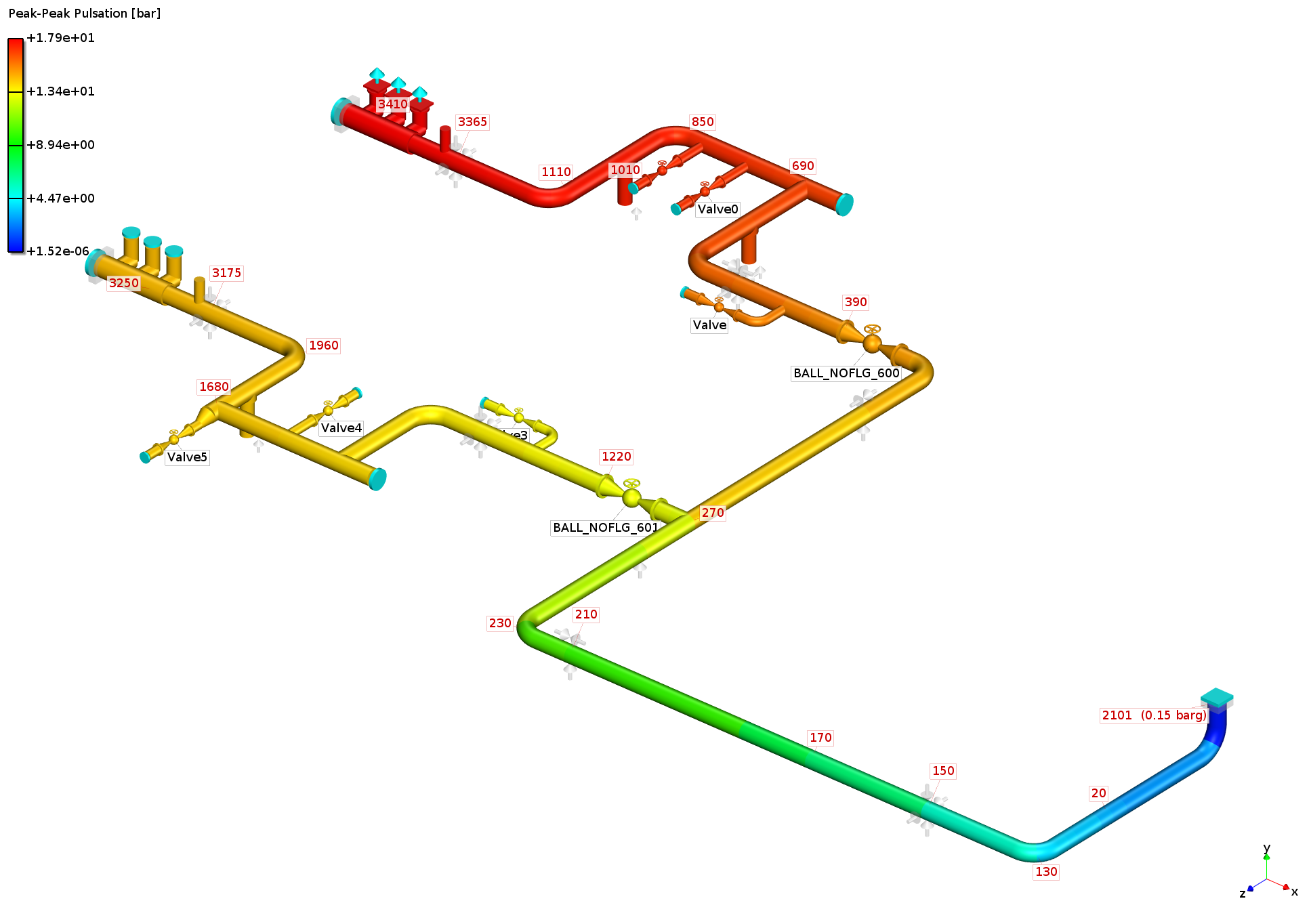

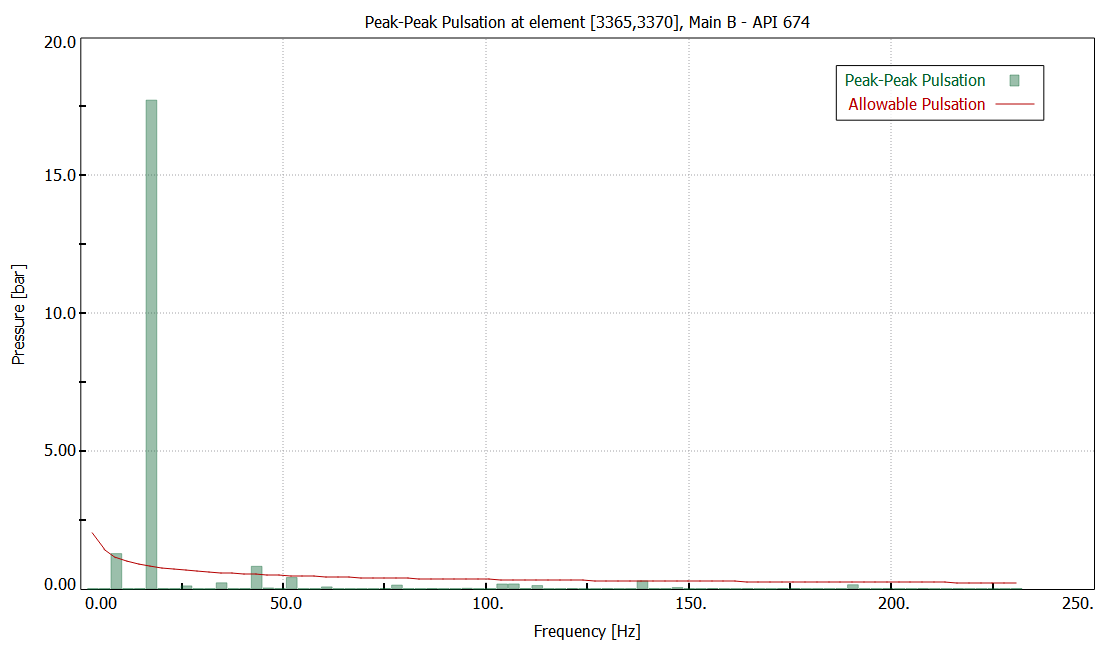

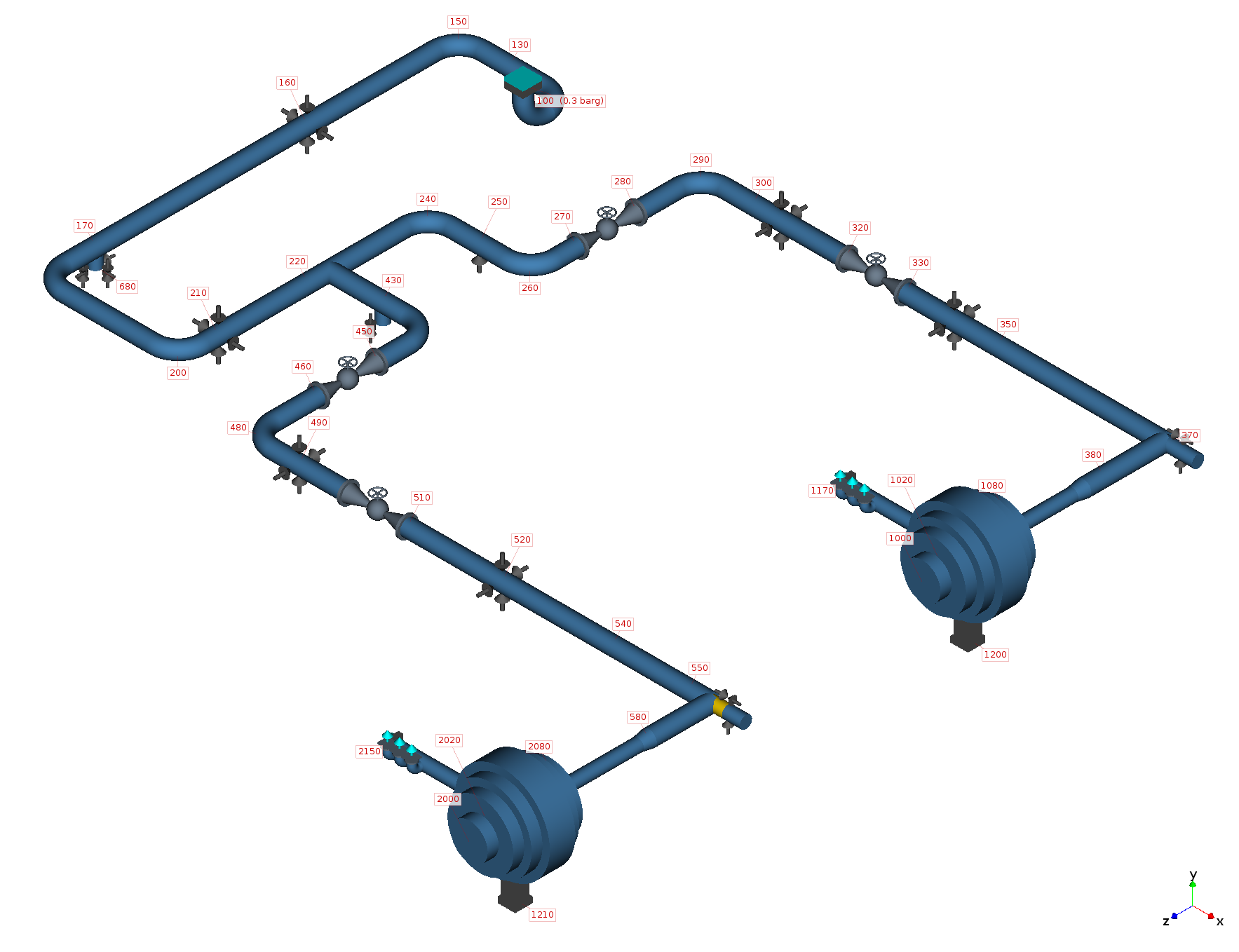

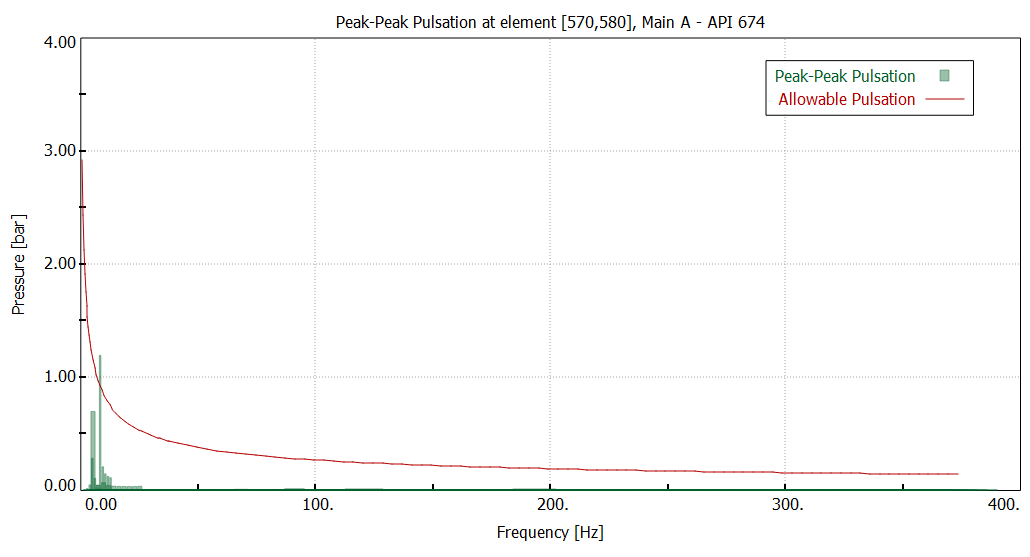

An acoustic system is modeled with detailed piping

drawings, liquid properties and equipment information. Peak-to-Peak Pulsation

Levels are calculated at the operating conditions and pump pressure steps are

chosen to yield the highest expected pulsation amplitudes throughout the piping

system. Pulsation amplitudes are then compared to the levels identified in API

674.

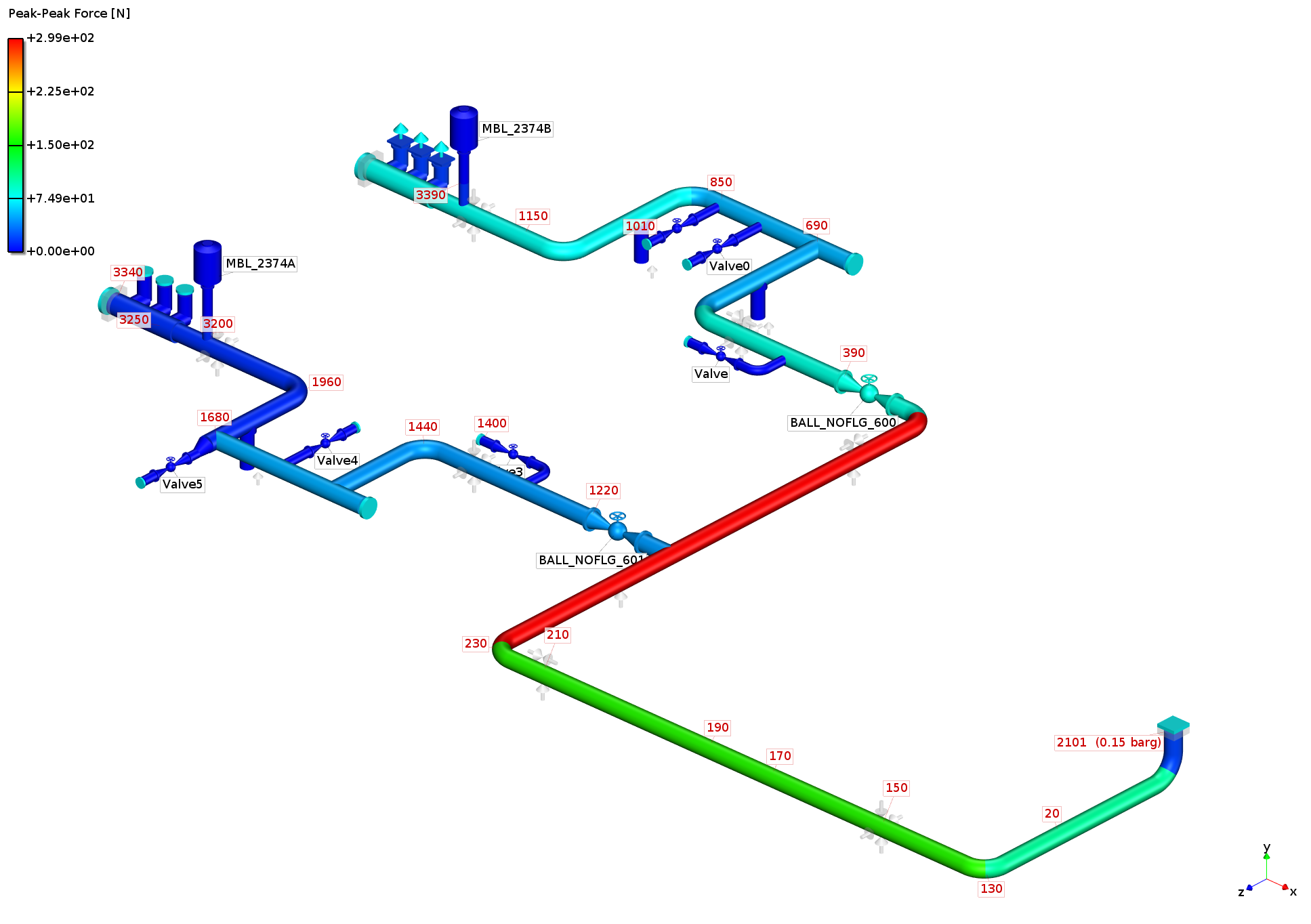

Pulsation-Induced Shaking Forces (Unbalanced Forces)

are calculated to predict the maximum pulsation-induced shaking forces and

unbalanced pressure acting on the critical elements of the piping system, such

as pulsation control devices, pulsation control device internals, vessels,

closed-end headers.

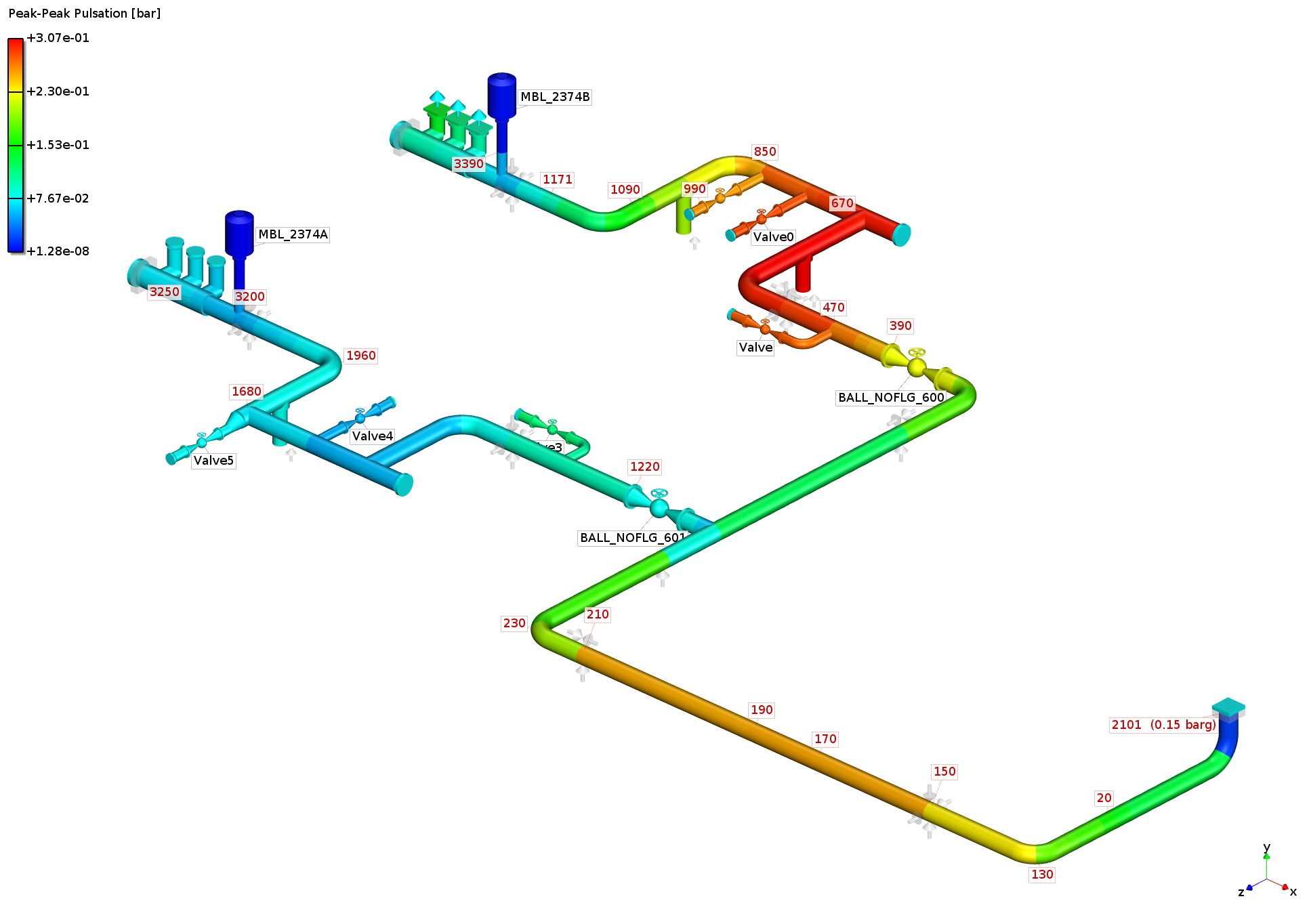

Piping Modifications are developed in the model if the

pulsation analysis indicates that pulsation levels and/or shaking forces are

excessive; modifications to the pulsation control devices and/or piping systems

are made and the analysis continued until the system meets the guidelines

defined in C.1.5 or other criteria as agreed upon by the Purchaser and Vendor.

A simple mechanical review shall be performed using

span and vessel mechanical natural frequency calculations to avoid mechanical

resonance. This review shall result in a table of various pipe sizes that

indicates the maximum allowable span (based on the maximum pump operating

speed) between piping supports as a function of pipe diameter, and the

separation margin requirements of API 674.

Design Approach 1

This simplified analytical study includes the design

of a pump pulsation suppression device using proprietary and/or empirical

analytical techniques to meet the pulsation levels specified in API 674 This

approach includes the study, good piping layout, good support/restraint

principles, and adequate NPIP to design a pulsation solution.

Model is generated in accordance with a simple

schematic diagram made available by the client. No extensive piping drawings

are required. This method provides a good quantitative overview of the basic

pressure pulsation behavior in the pipeline and pulsation dampener sizing.

Calculations and practice:

Suction system

model

Analysis:

simulation without pulsation dampener

Analysis:

simulation with optimum dampener configuration

Minimum pressure at pump inlet port

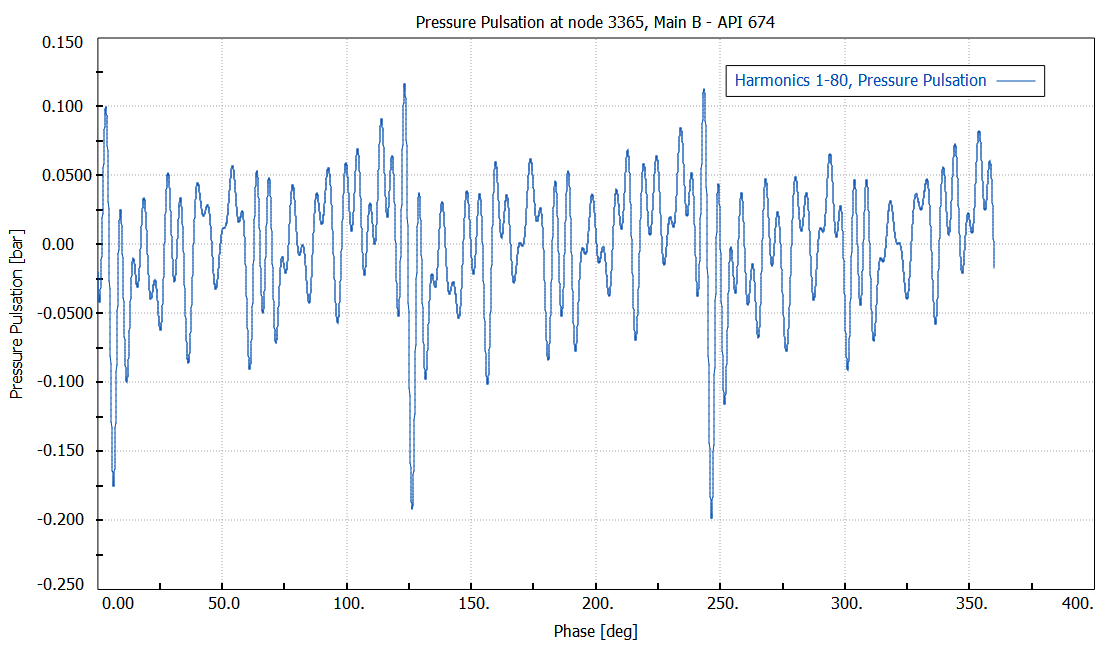

Pressure

pulsation at pump inlet port

--

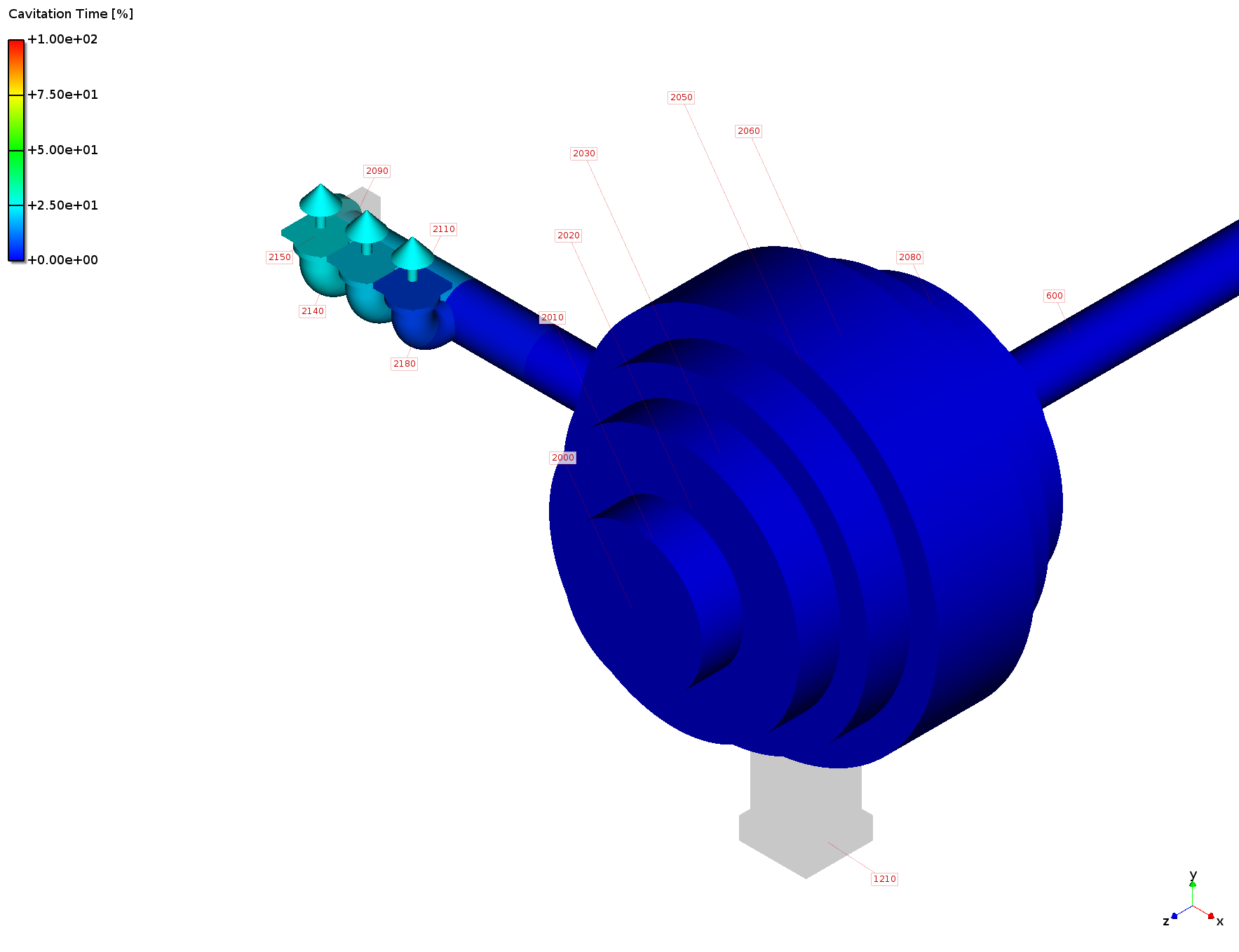

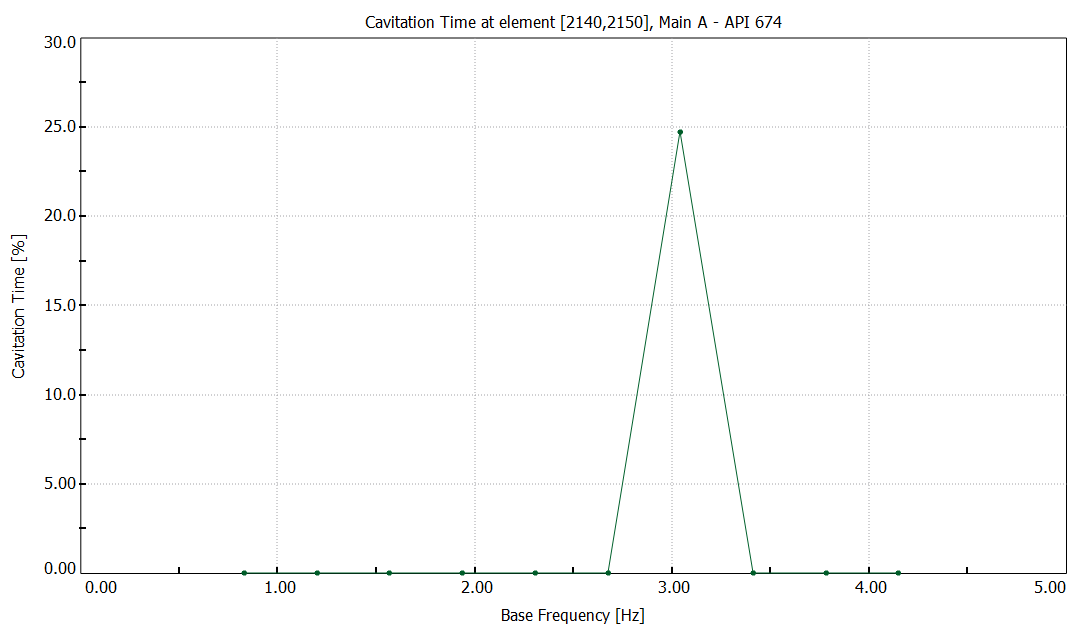

Analysis:

simulation with variable speed pump

Analysis:

cavitation time [%] over speed range

--

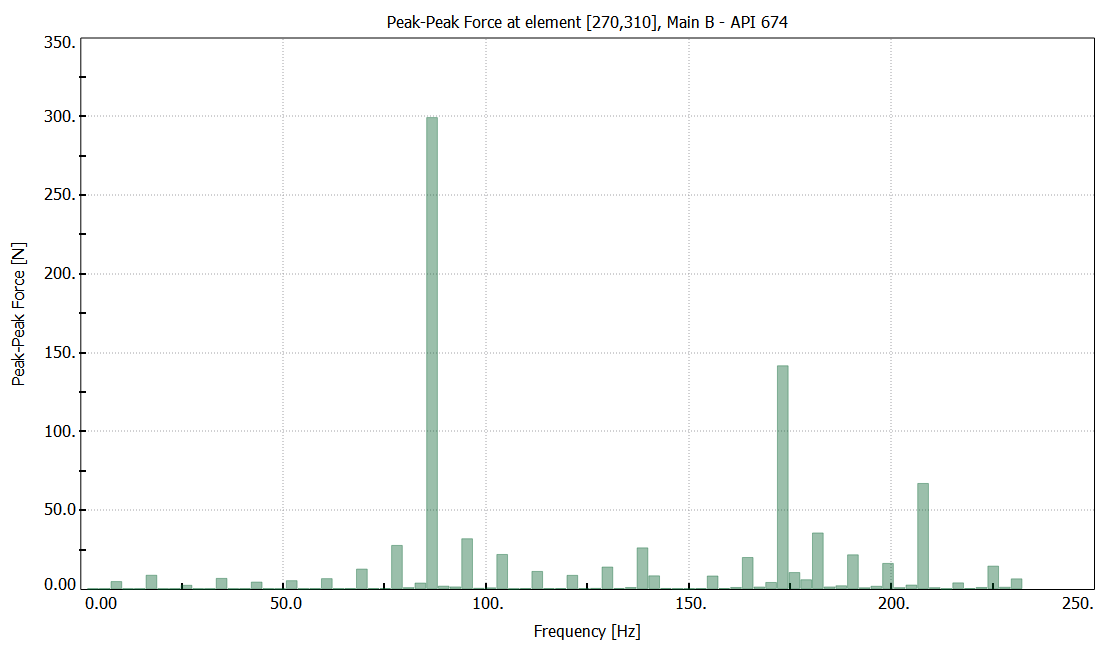

Force [N]

Spectra with pulsation dampeners

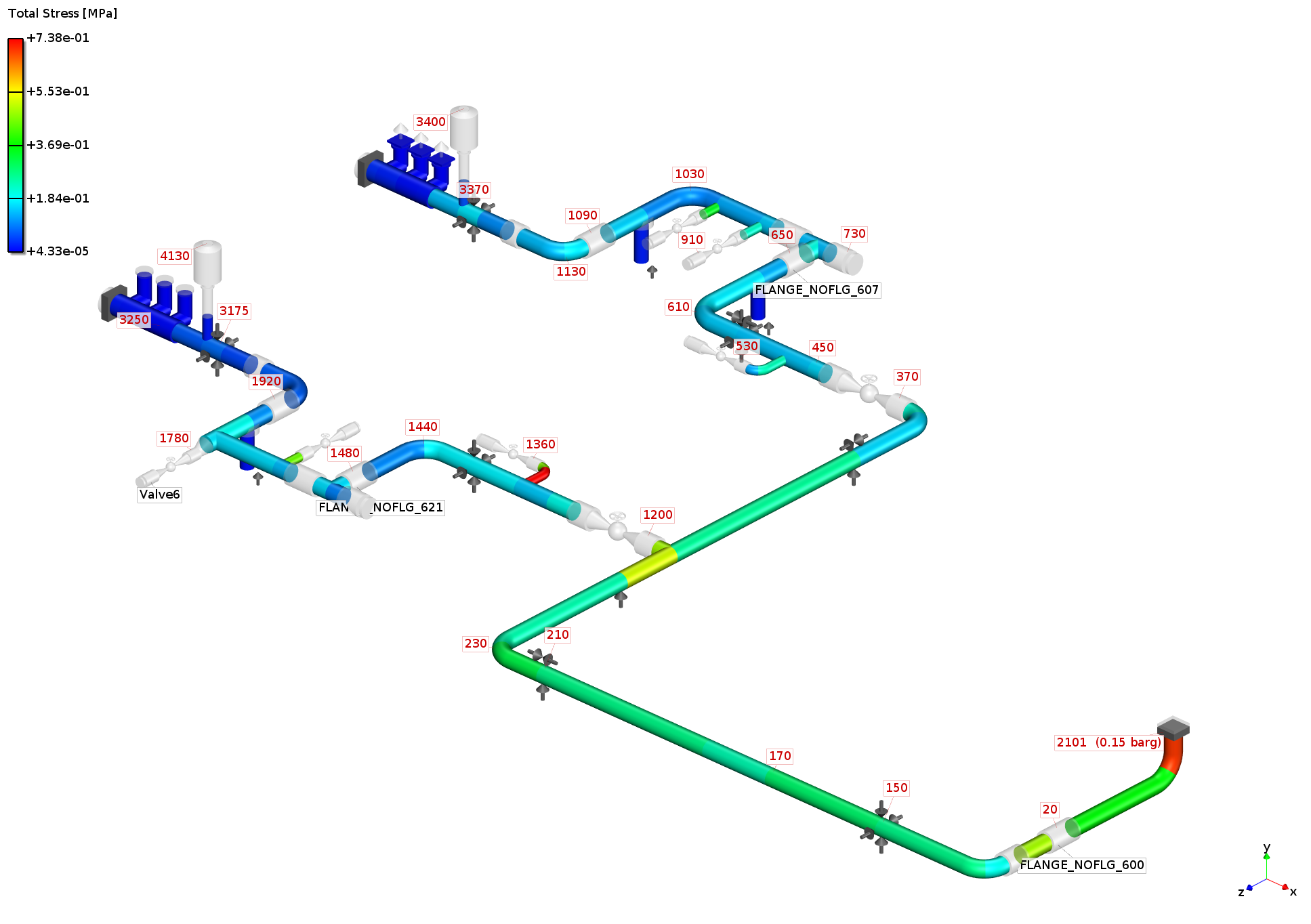

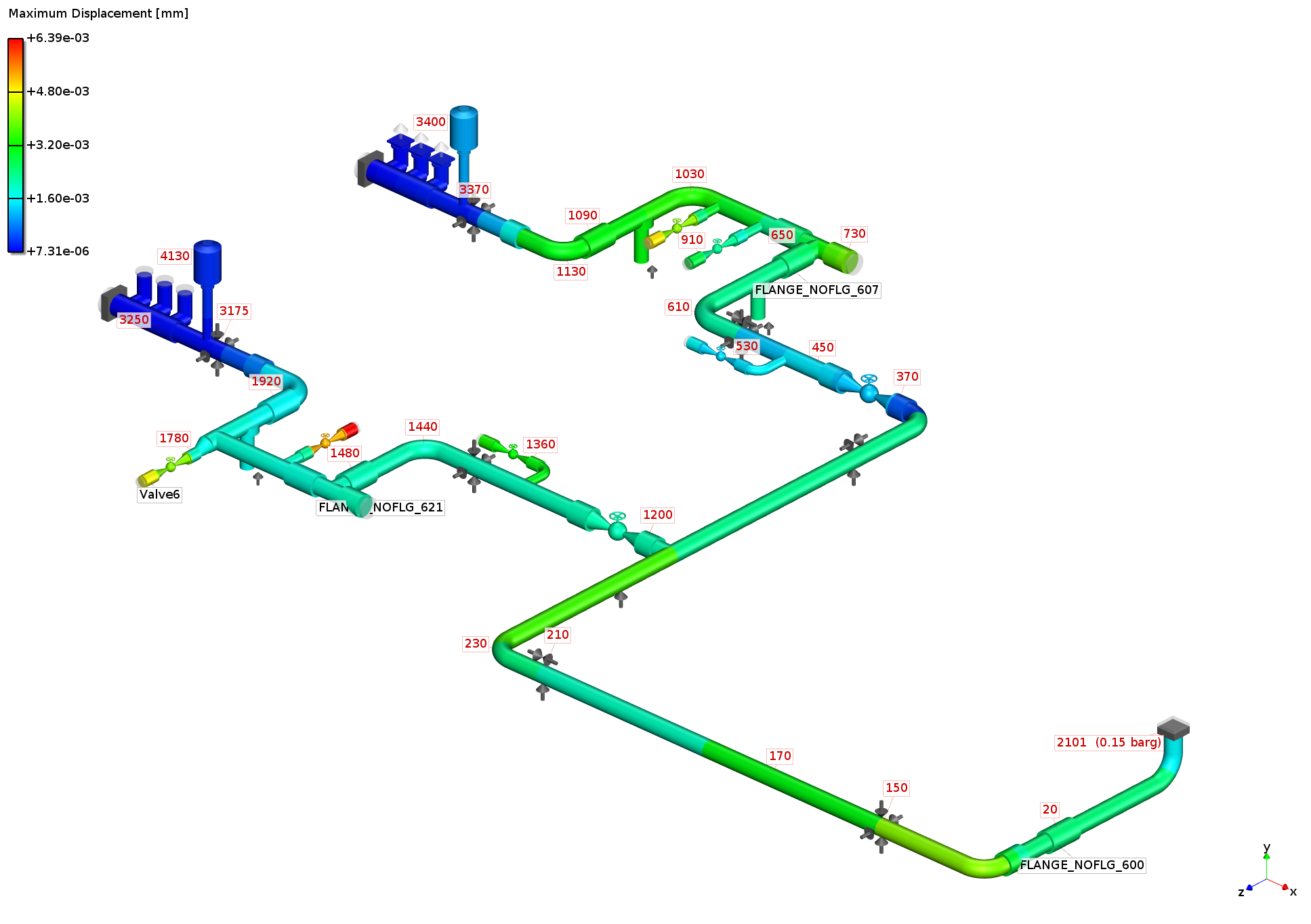

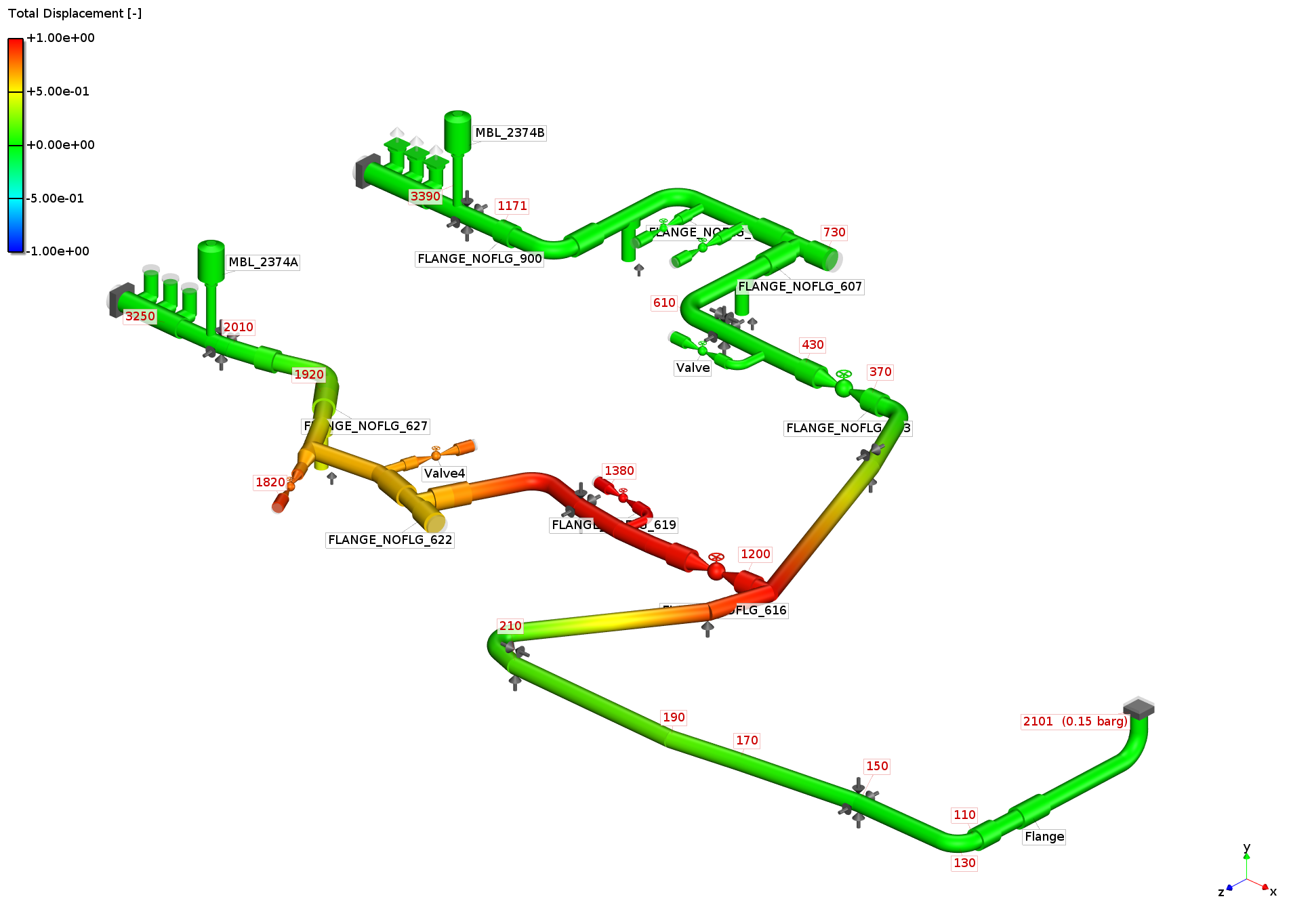

Analysis: Total

Stress and total displacement induced by acoustic pressure pulsations

1 st Mode @ 13.3 Hz

Analysis: Modal

analysis of piping system (Piping Natural Frequencies)